What is a Cobra Duct Rod used for?

Standard Cobra Duct Rod systems – Common Applications

- Installing cables or lines in ducts, tubes, conduit and pipes. These cable pulling systems enable many types of cables to be pulled through including pulling fibre optic cables by telecoms contractors.

- Threading draw ropes through pipes to pull winch ropes through ducts

- Surveying drains with CCTV cameras to identify issues or blockages on screens above ground

- Provide a faster and more efficient alternative to screw-together drain rods

- Removing blockages

Additional applications for Traceable Cobra Duct Rod Systems

- Tracing ducts using sondes and cable avoidance tools (e.g. CAT and Genny) to identify route location from above ground

- Locating underground blockages

- Maintaining visibility of expensive equipment when used in ducts and pipes – increasing expensive cameras and other equipment are being used in ducts and pipes and continual locating of this equipment is important to prevent loss

Industries that commonly use Cobra Duct rod systems

Telecommunications

Cobra duct rodding systems are widely used within the telecommunications industry to support the installation and maintenance of communication networks. Designed for professional cable installation, they provide a reliable method of feeding cables through underground ducts, conduit systems and internal trunking in both external and indoor environments.

High and Low Voltage Compatibility: Cobra duct rods are suitable for installing both high and low voltage cables, including fibre optic networks which form the backbone of modern communications infrastructure. Whether pulling power cables or data lines, the system enables smooth and controlled cable installation through pre-installed ducting.

Overcoming Obstacles: Telecom installations frequently involve long duct runs, tight bends and restricted access points. The balance of flexibility and tensile strength in Ritelite’s Cobra fibreglass rods allows engineers to navigate these challenges efficiently. When used with the appropriate accessories, cables can be installed with reduced risk of snagging, damage or unnecessary rerouting.

Efficiency and Cost Savings: Efficient cable deployment is critical in telecom projects where timelines directly impact service delivery. Duct rodding systems reduce labour-intensive pulling methods and minimise the likelihood of cable damage during installation. This helps improve installation speed, reduce remedial work and maintain project schedules.

Maintenance and Repairs: Beyond initial installation, duct rods also support network maintenance and repair work. When faults occur, technicians can use the system to locate, access and replace damaged cable sections with minimal disruption. This contributes to faster fault resolution and reduced network downtime.

Electricity and plumbing

Professionals working in electrical and plumbing installations often deal with complex networks of cables, conduits and pipework. Efficient cable pulling and reliable access to ducting systems are essential to keeping projects on schedule.

Fast and Efficient Cable Pulling: Cobra duct rods are available in a range of diameters to suit different conduit sizes and installation requirements. This allows electricians and plumbers to pull cables through ducts, pipes and trunking efficiently, whether working on small internal installations or larger infrastructure projects. Faster cable installation helps reduce downtime and improves overall project efficiency.

Blockage Detection and Resolution: Blocked conduits and pipework can delay installations and increase labour time. Duct rod pushers fitted with appropriate attachments enable technicians to locate obstructions quickly and assess the issue before further work begins. This reduces unnecessary disruption and supports a more controlled approach to resolving blockages.

Multi-Purpose Application: Beyond cable pulling, duct rods can be used for tasks such as feeding draw ropes and assisting with light cleaning when fitted with suitable attachments. This versatility makes them a practical tool for maintaining both electrical conduit systems and plumbing pipework.

Adaptability Across Projects: From residential wiring to commercial and industrial installations, the ability to select the correct rod diameter and accessories ensures the system can be matched to the demands of the job. This flexibility is important where duct sizes, pipe layouts and access conditions vary significantly.

Reduced Manual Strain: Manual cable pulling and pipe access can be physically demanding. Using a structured duct rodding system reduces the need for excessive manual force, supporting safer working practices while improving productivity on site.

Ongoing Maintenance and Repairs: In addition to installation work, duct rods assist with maintenance and fault-finding. They provide straightforward access to conduit and pipe runs, enabling technicians to diagnose and address issues efficiently, whether repairing electrical connections or investigating plumbing faults.

In summary, Cobra duct rods provide a reliable and adaptable solution for professionals working across electrical and plumbing applications. Their strength, flexibility and compatibility with a wide range of accessories make them suitable for installation, maintenance and fault investigation tasks.

Detection and Route Location

Continuous traceable duct rods – the Ritelite Flexitrace and Quicktrace products, are fitted with an integrated copper core, allowing them to be located from above ground using signal generators and cable locating equipment. This makes them particularly valuable where underground ducting, pipework or cable routes need to be identified without excavation.

Utilities and Infrastructure Maintenance: Traceable duct rods are widely used to locate and confirm the route of buried pipes, conduits and cables. The copper core within the fibreglass rod enables accurate detection, helping teams plan maintenance, repairs or upgrades with minimal disruption.

Construction and Excavation: Before groundworks begin, confirming the position of existing services is essential. Traceable rods assist in mapping underground assets, reducing the risk of accidental strikes and supporting safer excavation practices.

Environmental and Municipal Services: Where groundwater monitoring systems, drainage networks or utility lines require inspection, traceable rods allow operators to identify underground routes quickly and accurately. This supports efficient maintenance and emergency response across public infrastructure.

Telecommunications and Fibre Networks: In fibre optic installations, traceable rods assist with route verification and fault investigation. Being able to detect the position of underground ducting simplifies troubleshooting and reduces downtime during network maintenance.

Surveying and Specialist Applications: Surveyors and specialist contractors use traceable rods to map subsurface features as part of land development and infrastructure planning projects. Reliable detection data supports accurate documentation of underground services.

In summary, continuous traceable duct rods provide a controlled and efficient method of locating underground ducts, pipes and cables. By enabling accurate route identification from above ground, they help improve safety, reduce unnecessary excavation and support effective infrastructure management across multiple sectors.

How Ritelite Traceable Rodding Systems Offer Two Methods of Duct Locating

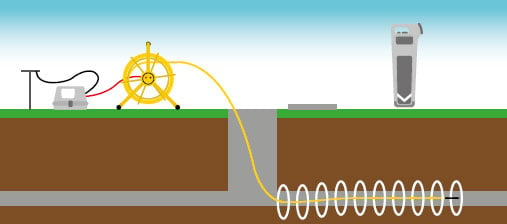

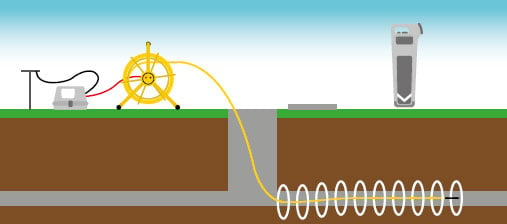

Quick Trace Method

The Quick Trace system incorporates copper wires embedded within the rod, enabling the rod to be fully traceable once connected to a signal generator.

When used in line mode, the entire length of the rod can be detected from above ground using compatible cable avoidance tools such as a CAT and Genny. This method is particularly effective for confirming duct routes and identifying the position of underground services over longer distances.

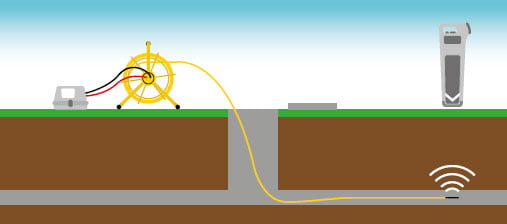

Flexitrace Method

The Flexitrace continuous trace system provides a compact and labour-saving solution for locating non-metallic ducts and drains.

This system combines the functionality of both a continuous trace system and a sonde in a single unit. Users can switch between:

Line Mode – tracing the full length of the rod

Sonde Mode – locating the rod tip precisely

This dual capability allows for accurate route tracking as well as pinpoint identification of the rod’s end position.

Frequently Asked Questions about Cobra Duct Rods

What is a duct rod used for?

What is the difference between a duct rod and a drain rod?

Drain rods are usually sectional, screw-together rods designed for clearing blockages in drainage systems. Duct rods are engineered specifically for cable installation and route locating applications.